Used Shacman F3000 Concrete Mixer Truck 6*4

1. Efficiency: Concrete Mixer Trucks offer a high level of efficiency by combining the transportation and mixing of concrete in a single vehicle. This eliminates the need for additional equipment or manpower to mix concrete on-site, saving time and labor costs.

2. On-Time Delivery: Concrete Mixer Trucks ensure the timely delivery of freshly mixed concrete to construction sites. The ability to mix concrete during transportation helps prevent delays and ensures that the concrete remains workable upon arrival.

3. Consistent Quality: The mixing process in a Concrete Mixer Truck is controlled and consistent, resulting in a uniform and high-quality concrete mix. This helps maintain the desired strength and durability of the concrete for construction projects.

4. Versatility: Concrete Mixer Trucks are versatile and can navigate various types of terrain and job sites, providing flexibility in delivering concrete to different locations. They can access hard-to-reach areas on construction sites, ensuring concrete can be delivered wherever needed.

5. Cost-Effective: Using a Concrete Mixer Truck can be cost-effective in the long run by reducing the need for additional equipment, labor, and material handling. The efficiency and convenience of on-site mixing and delivery can lead to cost savings for construction projects.

6. Reduced Waste: Concrete Mixer Trucks help minimize waste by delivering the exact amount of concrete needed for a project. This reduces overordering and leftover concrete, leading to cost savings and environmental benefits.

Controls: The driver of the Concrete Mixer Truck has controls inside the cab to operate the rotation of the drum, control the speed of mixing, and discharge the concrete when needed. These controls allow the driver to monitor and adjust the mixing process as required.

Hydraulic System: Concrete Mixer Trucks are equipped with a hydraulic system that powers the rotation of the drum and controls the discharge of the concrete. This system provides the necessary force to operate the mixer efficiently.

Drive System: Concrete Mixer Trucks are typically rear-wheel drive or all-wheel drive to provide the necessary traction and stability when navigating construction sites or rough terrain. The drive system ensures that the truck can deliver concrete to various locations on the job site.

Capacity: Concrete Mixer Trucks come in various sizes and capacities, ranging from small transit mixers for residential projects to large trucks for commercial construction sites. The capacity of the mixer drum determines the amount of concrete that can be transported in a single trip.

Safety Features: These trucks may include safety features such as backup cameras, warning lights, and reflective markings to ensure the safety of the operator and other road users.

Overall, Concrete Mixer Trucks play a crucial role in the construction industry by transporting and mixing concrete on-site, offering features such as a mixer drum, water tank, agitator blades, charging hopper, controls, hydraulic system, drive system, capacity options, and safety features to facilitate the efficient delivery of high-quality concrete to construction projects.

Concrete Mixer Truck | |

Applicable Industries | Building Material Shops, Construction works ,Energy & Mining, Other |

Showroom Location | China |

Video outgoing-inspection | Provided |

Machinery Test Report | Not Available/Provided |

Core Components | Engine, Bearing, Gearbox, Motor, Gear, Pump |

Condition | Used/New |

Weight | 12500 KG/15500 kg/8850 KG/6800 kg/14200 kg/7325 kg/16150 KG |

Place of Origin | Shandong, China |

Product name | concrete mixer truck |

Engine | 336HP, emission: EURO II/Weichai 350/CM6D18, 375 50/WP10.340E22 |

Color | Customers Optional |

Brand Name | HOWO/SHACMAN/XCMG |

Dimension(L*W*H) | 6500*2400*3200 mm/9000*2500*3920mm/9480*2490*3450 |

Certification | ISO CE |

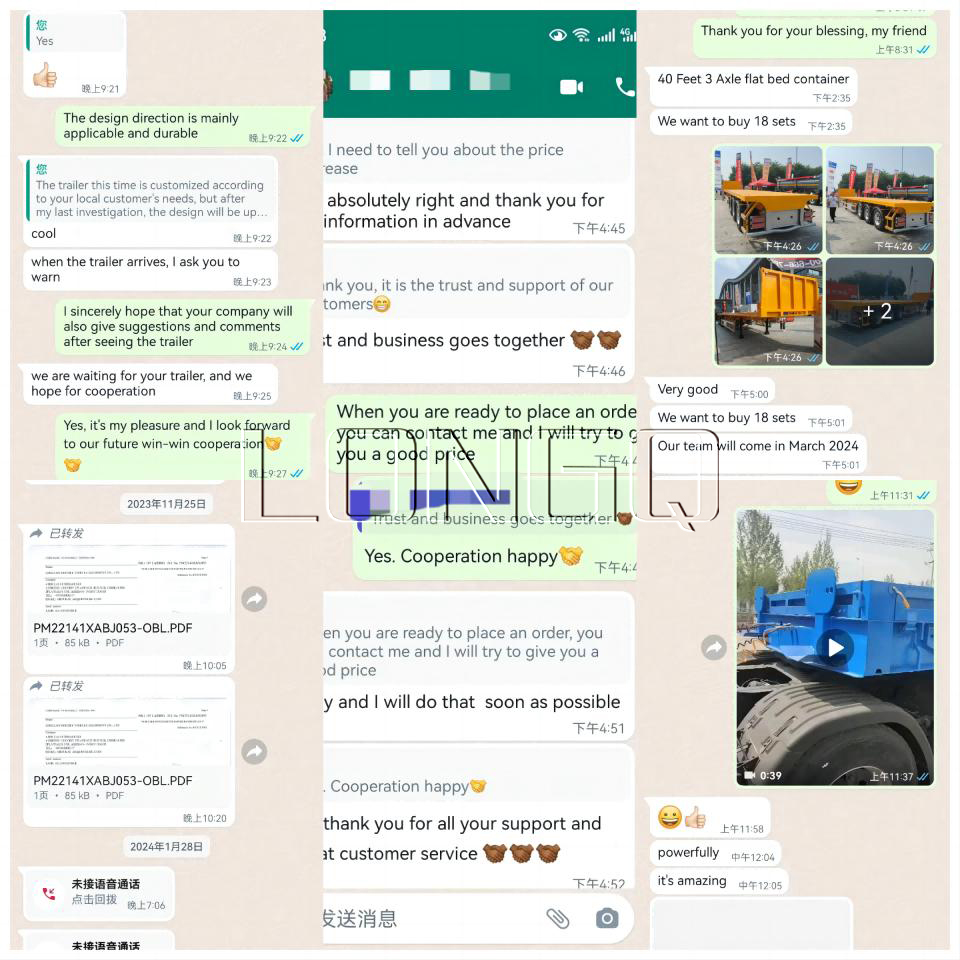

Customer Feedback

Customer Visiting

PACKAGING & SHIPPING

Related News

Submitted successfully

We will contact you as soon as possible