Used Sinotruk Howo Cement Mixer Truck

1. Efficiency: Concrete Mixer Trucks offer a high level of efficiency by combining the transportation and mixing of concrete in a single vehicle. This eliminates the need for additional equipment or manpower to mix concrete on-site, saving time and labor costs.

2. On-Time Delivery: Concrete Mixer Trucks ensure the timely delivery of freshly mixed concrete to construction sites. The ability to mix concrete during transportation helps prevent delays and ensures that the concrete remains workable upon arrival.

3. Consistent Quality: The mixing process in a Concrete Mixer Truck is controlled and consistent, resulting in a uniform and high-quality concrete mix. This helps maintain the desired strength and durability of the concrete for construction projects.

4. Versatility: Concrete Mixer Trucks are versatile and can navigate various types of terrain and job sites, providing flexibility in delivering concrete to different locations. They can access hard-to-reach areas on construction sites, ensuring concrete can be delivered wherever needed.

5. Cost-Effective: Using a Concrete Mixer Truck can be cost-effective in the long run by reducing the need for additional equipment, labor, and material handling. The efficiency and convenience of on-site mixing and delivery can lead to cost savings for construction projects.

6. Reduced Waste: Concrete Mixer Trucks help minimize waste by delivering the exact amount of concrete needed for a project. This reduces overordering and leftover concrete, leading to cost savings and environmental benefits.

A Concrete Mixer Truck, also known as a cement mixer truck or transit mixer, is a specialized vehicle used to transport and mix concrete from the batching plant to construction sites. These trucks are essential in the construction industry for delivering freshly mixed concrete to various construction projects, such as buildings, roads, bridges, and other infrastructure developments.

Key features and components of a Concrete Mixer Truck include:

Mixer Drum: The most prominent feature of a Concrete Mixer Truck is the rotating drum located at the rear of the vehicle. This drum is where the concrete ingredients are mixed together during transportation. The drum rotates in one direction to mix the concrete and in the opposite direction to discharge the concrete.

Water Tank: Concrete Mixer Trucks are equipped with a water tank that stores water to be added to the concrete mix during transportation. The water tank ensures that the concrete remains workable and maintains the desired consistency.

Agitator Blades: Inside the mixer drum, there are agitator blades that help mix the concrete ingredients thoroughly. These blades ensure that the cement, aggregates, water, and additives are evenly distributed to produce a uniform concrete mix.

Charging Hopper: Concrete Mixer Trucks have a charging hopper at the top of the drum where the concrete ingredients are loaded from the batching plant. The hopper is equipped with a chute or conveyor system for easy loading.

Concrete Mixer Truck | |

Applicable Industries | Building Material Shops, Construction works ,Energy & Mining, Other |

Showroom Location | China |

Video outgoing-inspection | Provided |

Machinery Test Report | Not Available/Provided |

Core Components | Engine, Bearing, Gearbox, Motor, Gear, Pump |

Condition | Used/New |

Weight | 12500 KG/15500 kg/8850 KG/6800 kg/14200 kg/7325 kg/16150 KG |

Place of Origin | Shandong, China |

Product name | concrete mixer truck |

Engine | 336HP, emission: EURO II/Weichai 350/CM6D18, 375 50/WP10.340E22 |

Color | Customers Optional |

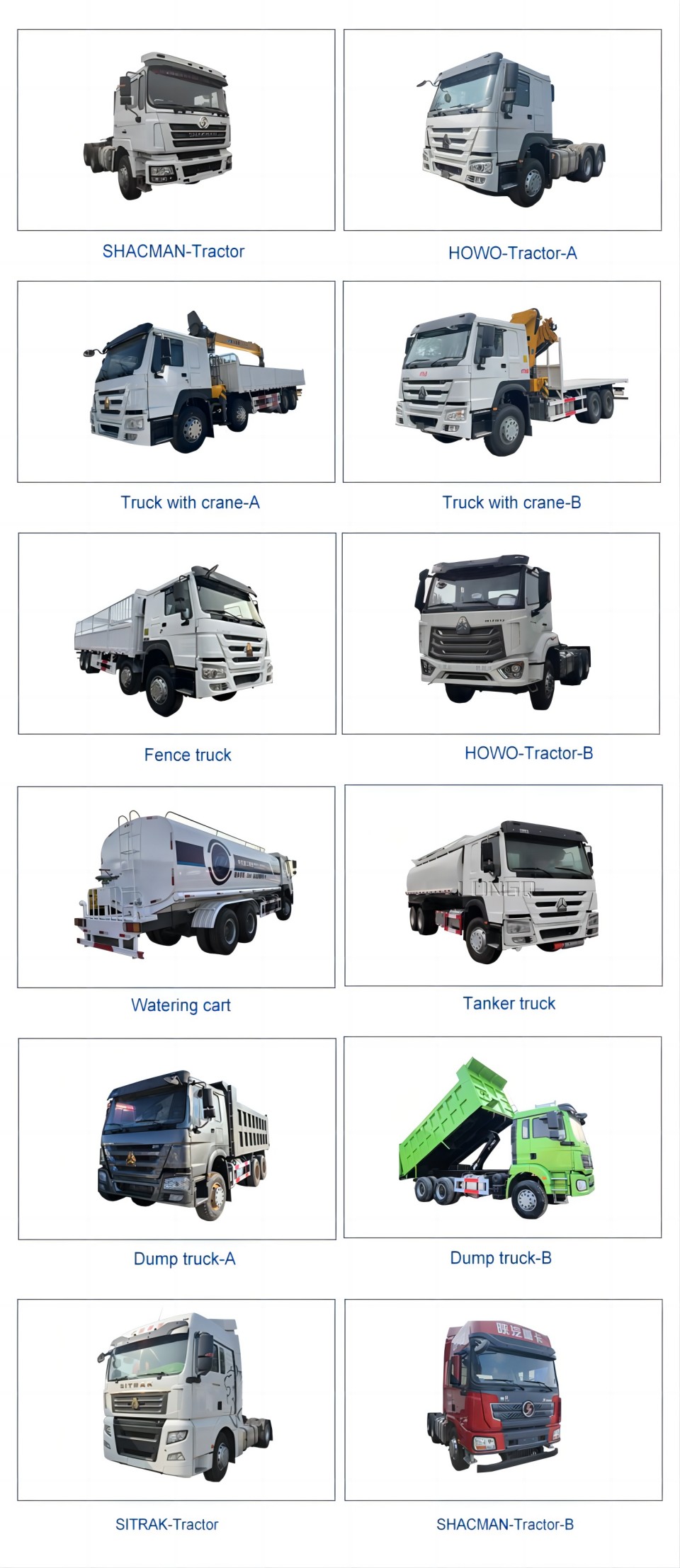

Brand Name | HOWO/SHACMAN/XCMG |

Dimension(L*W*H) | 6500*2400*3200 mm/9000*2500*3920mm/9480*2490*3450 |

Certification | ISO CE |

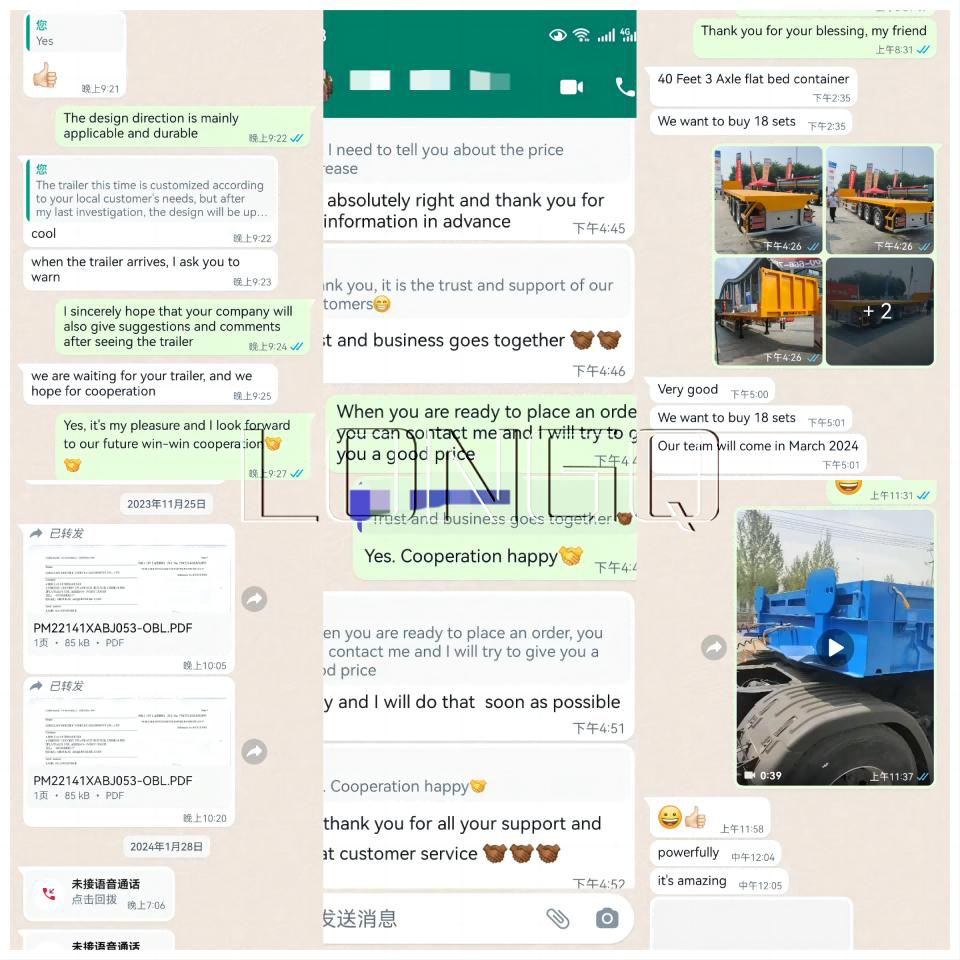

Customer Visiting

PACKAGING & SHIPPING

Related News

Submitted successfully

We will contact you as soon as possible